http://www.newrolik.narod.ru |

MAIN |

Theory | Technologies | Authors | Literature | Handbook | По русски |

THREAD-ROLLING DIES OF HIGH WEAR RESISTANCE

Thread rolling is one off the most progressive ways of producing threads. It provides high efficiency and quality of treatment. But in case of producing coarse trapezoidal threads and threads on preliminary strengthened materials thread rolling is economically inefficient due to poor wear resistance of the tool used. When rolling treads whit axial feed (by means of thread-rolling heads or chipless taps) high tool breakage is due to ununiform loading of turns of thread-forming part. Traditional methods of profiling thread-forming part of a toll (Fig. 1) fail to provide uniform loading of all its turns resulting in rapid wearing of breakage of the most loaded turn.

Fig. 1. Dependence of instant contact area of tool and workpiece on the method of profiling the thread-forming part of tool for rolling external threads:

1 - constant radial elevation (angle of coneis 10°); 2 - arithmetic progression; 3 - parabola; 4 - circle; 5 - hyperbola; 6 - suggest method.

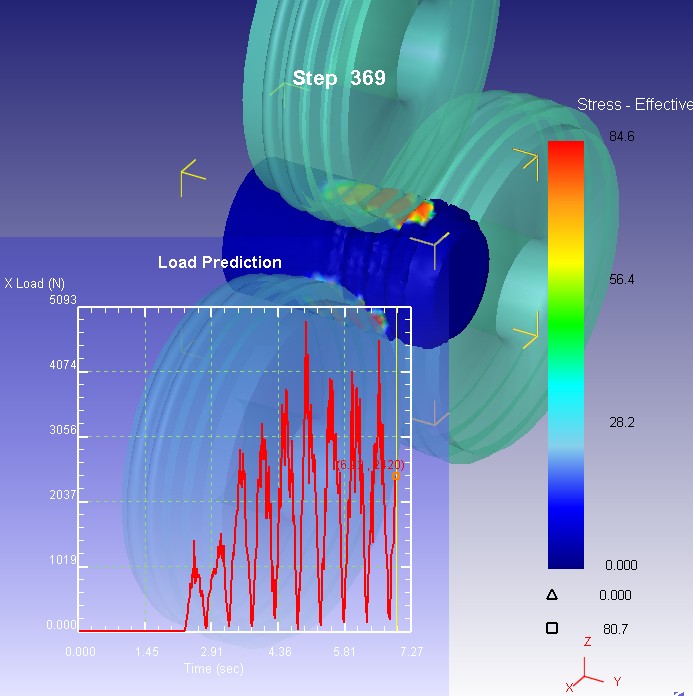

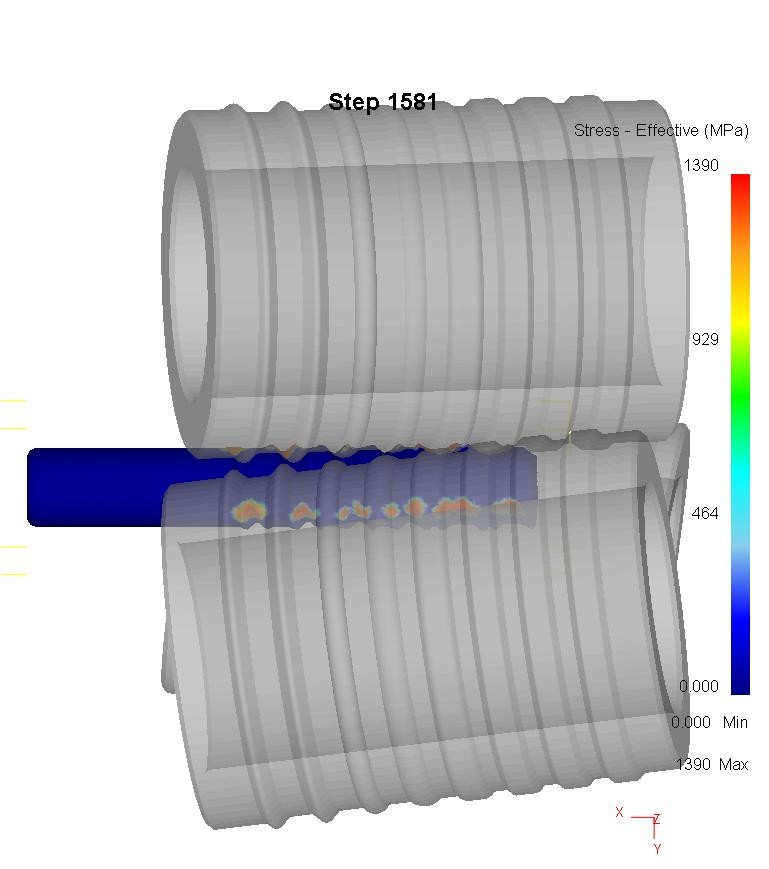

As the contact pressure are directly proportional to the instant contact area of tool and workpiece (ICA), the scientists worked out original method of profiling thread-forming part of tool for rolling external and internal triangular, round and trapezoidal threads which is based on calculation ICA (Fig. 2) for each turn and finite element analysis stress and strain (Fig. 3). All the details of the suggested method can be found in special literature. Tolls designed according to this method (Fig. 4) have wear resistance twice as much than the traditional ones.

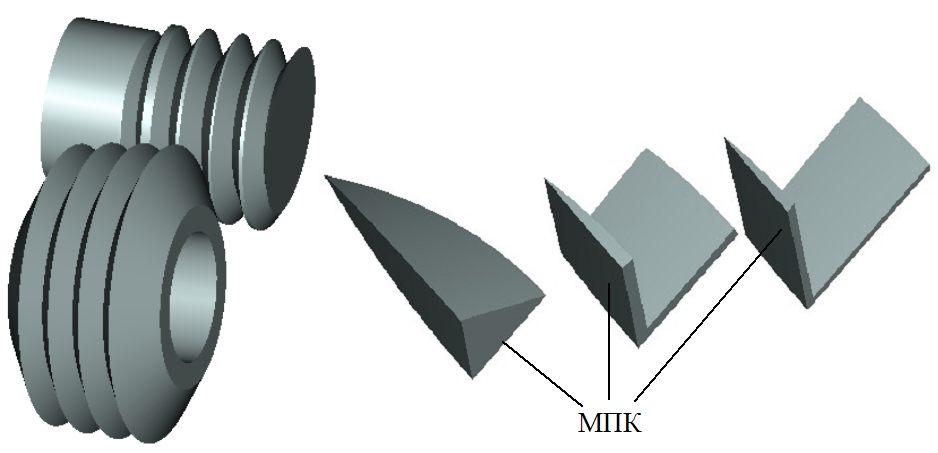

Fig. 2. Three-dimensional geometrical model of a contact area at a thread rolling.

Fig. 3. Effective Stress von Mises at a threads rolling of a axial head.

Fig. 4. Rollers for producing external trapezoidal thread.

Research was financed by the grant of the president of the Russian Federation and Ministery of Edication . The results of the research were successfully put into practice at a number of industrial enterprises. On designed thread rolling tools and technology of a rolling of threads are received more than 20 patents of the Russian Federation for the invention and for useful model. The group of authors suggests the engineering and designing of the high-life circular thread rolling dies for thread rolling machines and heads.

The authors offer services in perfecting technology of thread forming (engineering of the special equipment, the combined cutting-forming handling, etc.).

Besides, the authors suggest the technological method of static-impuls deformation strengthening of the machine part surfaces.

You can contact us by E-mail: newrolik@narod.ru

http://www.newrolik.narod.ru |

MAIN |

Theory | Technologies | Authors | Literature | Handbook | По русски |